ABOUT US

Our History

Since 1966, companies have come to rely on our customized Engineered Cooling Systems and Enclosures to work in the toughest industrial industries and most severe environmental conditions.

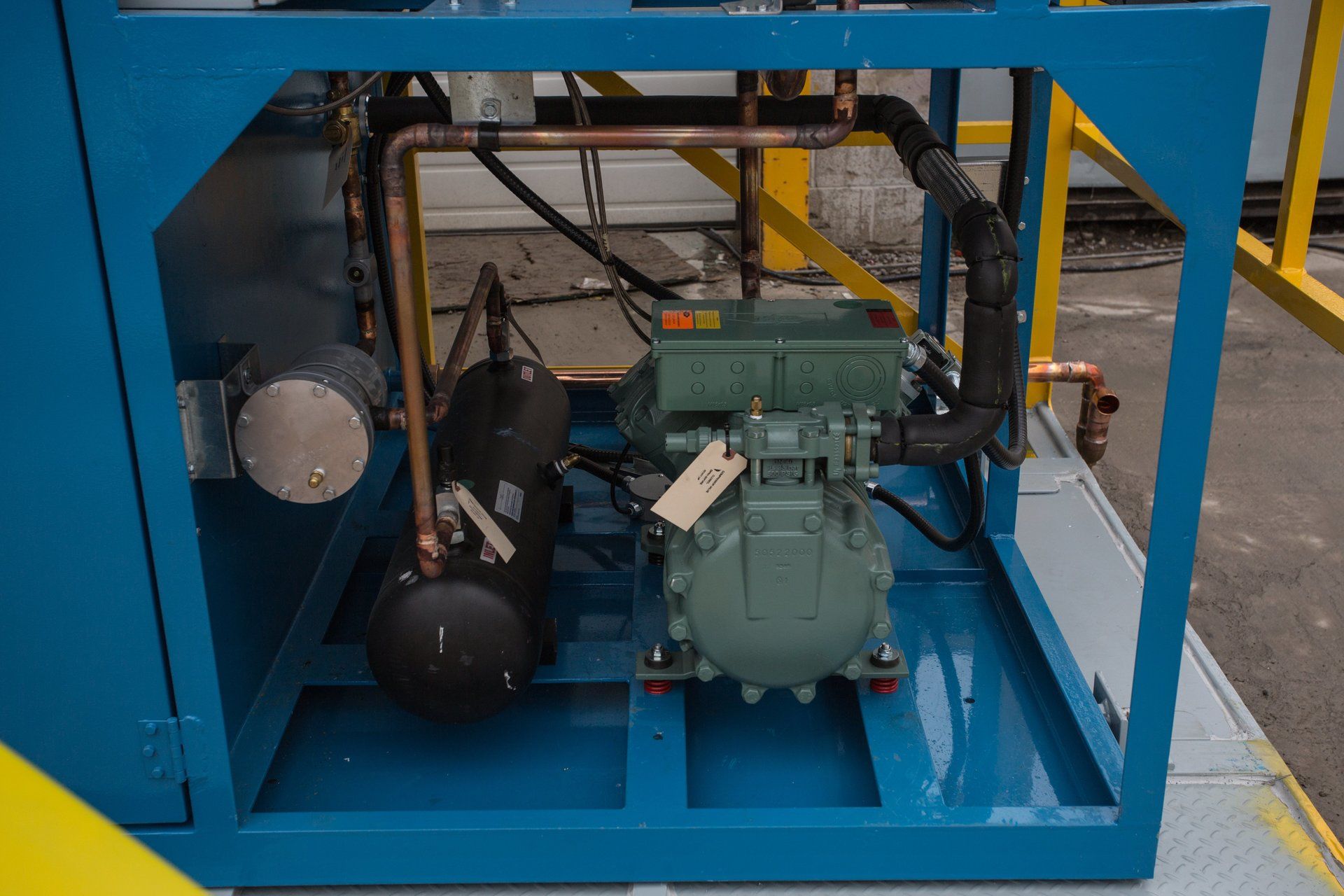

Philip Doyle Manufacturing offers both standard and customized Operator Cabins, Control Room Enclosures and Industrial Air Conditioners. Choose from our standard designs or select from a list of optional features to customize any of the products to your specific requirements. All units are designed and engineered to provide low maintenance and robust accommodation.

We design and manufacture Cabs and Enclosures in light, medium and severe duty construction. Our HVAC solutions reflect your unique needs and designed to withstand heavy-duty applications in the harshest conditions.

No matter what the application or product, we put personal service and customer satisfaction first!

Philip Doyle

Philip Doyle has a long history of design, engineering and manufacturing expertise, ensuring all units withstand any type of environment. Our design team understands the unique requirements for all units to continue performing at top-condition, providing an ideal solution for heavy or continuous duty in hot, dirty, dusty, corrosive, and severe conditions.

We offer Cabs and Enclosures in light, medium and severe duty construction. Our hermetically sealed units protect your electrical control equipment, control humidity and prevent excessive fumes that cause operator discomfort - such as headaches or eye irritations.

Our Industrial Air Conditioning has top-performance and optimal convenience designed into each unit. We offer a range of standardized units, but have earned a reputation with our customized solutions, specifically designed to suit customer’s specific requirements and conditions.

The staff at Philip Doyle boasts years of technical expertise and hands-on experience, always ready to assist you in the development or evaluation of the requirements for your environmental system through on-site support and assistance. We work with you to develop the best solution for your unique situation and our experts can assist you through teleconferencing or visiting you in-person to develop a detailed solution that will handle your requirements.

Company Certification

Quality Management System Certification

Philip Doyle Manufacturing Inc. is committed to a Quality Management System that conforms and is certified to ISO 9001.

Our management system conforms to the ISO9001

requirements where we demonstrate and aim to enhance customer satisfaction through the effective application of the system, including processes for continual improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements

Welding

Philip Doyle Manufacturing is a certified welding shop under CWB W47.1 Division 2 “Fusion Welding of Steel” and our welders are certified by CWB (Canadian Welding Bureau) group.

Philip Doyle Manufacturing qualifies its welders to AWS (American Welding Society) Standards D1.1 (Structural Welding Code – Steel) & D1.3:08 (Light Gauge)

Companies certified to CSA Welding Standards W47.1 Division 2

are required to employ qualified welders and welder supervisors, as well as have a welding engineer as a key part of their welding operations. Our welding engineer is responsible for welding related activities as specified by Philip Doyle Manufacturing. We are audited on our welding operations by both

CWB and our welding engineer to maintain our certification.

A welding supervisor is directly responsible for ensuring that qualified welders and welding operators are working in accordance to approved welding procedure data sheets on the shop floor or in the field.

A supervisor who is qualified under the CSA W47.1

standards ensures the company's welding procedures cover all joints, processes and positions used in fabrication/erection are current and approved by the CWB, and that weld quality and workmanship are up to the levels specified by the design or product standard. Each CWB

certified company is required to employ an adequate number of Welding Supervisors, with welding related experience, to control welding operations.

For certification to CSA Standard W47.1,

a company is compliant with CSA W47.1

“Fusion Welding of Steel” and CSA W59

“Welded Steel Construction”

Electrical Inspections Certification

To be successful on the market, the safety, quality, durability, and reliability of your products are essential. Manufacturers are responsible for ensuring the products they place on the market meet all relevant regulations. Ensuring customers receive safe components of high quality is critical to the longevity of your business.

Every part of an electrical appliance can be hazardous and one defective component can lead to disastrous results. Our experience and scope of accreditation help you meet local and global electrical product safety regulations. As one of the largest certifiers within the CB Scheme, TÜV Rheinland Group has vast experience in a broad range of product testing.

Homeowners should request a copy of the “Certificate of Inspection”

for all electrical work done in their homes/businesses.

An electrical inspection provides customers with a record that all electrical work in their home/business complies with the requirements defined in the Ontario Electrical Safety Code.

Once the electrical work has passed inspection, ESA will issue a Certificate of Inspection to the permit holder to confirm that the electrical work is in compliance with the Ontario Electrical Safety Code. If your contractor took out the permit, then you should request a copy of the Certificate from them for your records.