PRODUCTS

Some of the many products we design and manufacture include:

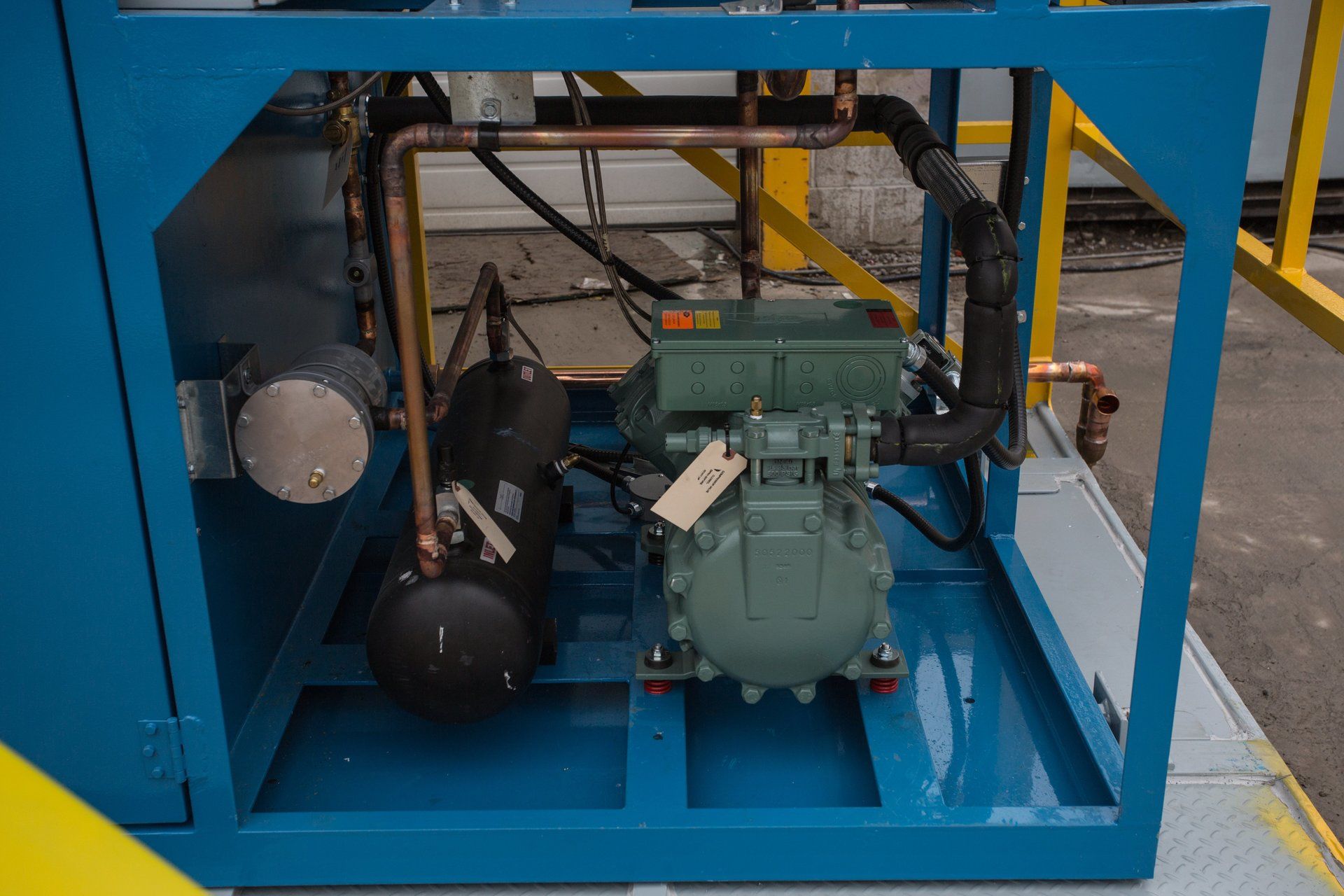

Air Conditioners (HVAC Units)

- Overhead Crane Systems (Cabins, Control Houses & Panel Cooling Systems)

- Stationary Enclosures (Pulpits, Electrical Rooms, Control Rooms)

- Mobile Systems

- Man-Cooler (spot-cooling) Once Through Systems

- Overhead Cranes

- Mill Pulpits

- Electrical Rooms

- Coke Oven Vehicles

Crane Cabin Air Conditioners:

Slide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

Button

Slide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

Button

Slide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

Button

Slide Title

Write your caption here

ButtonSlide Title

Write your caption here

Button

Slide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

Button

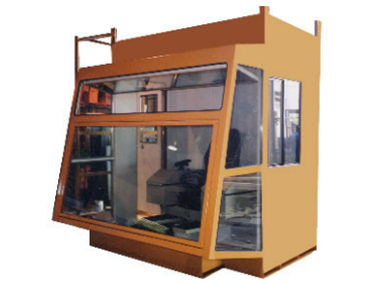

Enclosures

- Crane Operator Cabins

- Pulpits, Control Rooms, Operator Rooms

- Electrical Rooms, Prefabricated Control Panels

- Computer Rooms, Clean Rooms

- Can be transported with services installed

- Rugged industrial construction

- Patented sound resistant windows

- Individually designed

- Lighting

- Air-conditioning

- Acoustic ceiling

- Wiring raceways

- Interconnecting wiring

- Ductwork systems

- Custom shapes and designs

- Sloped walls and roof

- Airlocks

- Heat shield

- Raised access computer flooring

- Drive panels mounted and secured

- Customized acoustical doors

- Communication jacks

- Control panels and associated wiring

- Telephone equipment, TV monitor stands

- Fire detection and suppression systems

- Custom size and shaped windows

- Triple pane glass

- (IRR) infra-red radiant heat resistant

- Impact resistant and tinted windows

- Metal rolling window shields or shutters

- Sliding, hinged, sloped and emergency escape windows

- Chairs, control desks, custom tables, cabinets and shelves

- Fire detection and suppression systems

- Removable wall, roof or floor openings

- Floor and wall wire troughs and raceways

- Complete washrooms and kitchenettes

- Stairways, support platforms and decks with handrails

- Noise

- Extremely high or low temperatures

- Dust/Fumes or physical hazards

Pre-Fabricated Control Rooms (PCR):

Slide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

Button

Slide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

Button

- Rugged Industrial Construction

- Single Pane Windows

- Acoustically Rated Doors & Ceilings

- Lighting

- Air Conditioning

- Wiring Raceways

Slide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

Button

- Overhead Cabins

- Traveling Cabins

- Stationary Cabins

- Crane Cabins

- OEM’s – non-branded for major crane manufacturers

- Modernization turn-key projects to address operator comfort and safety needs

- Any industrial location with:

- Noise

- Extremely high or low temperatures

- Dust, fumes or physical hazards

- Rugged industrial construction

- Single pane windows

- Acoustically rated doors

- Can be transported with services installed

- Unique and individual requirements

- Maximizing lines of sight and minimize visual obstructions

- Ergonomic compliance

- North American standards

- Lighting

- Air conditioning

- Acoustic ceiling

- Wiring raceways

- Chairs and consoles

- Supply and return air distribution system

- Heat shield (floor and walls)

- Various insulation types dependent upon requirements

- Boarding platforms, ladders, stairs

- Swing gates

- Windshield wiper systems

- Amplified speakers, exterior mounted horns and signal lights

- Roof or floor escape hatch

- Safety grating for floor windows

- Safety mesh screens

- Safety bars on inside of windows to offer greater protection to operators

- Hinged and sliding windows

- Tinted windows

- Industrial sound resistant windows

- Acoustically rated doors

- Weatherproof enclosure

- Impact resistant safety glass

- IRR Infra-Red heat reflective glass

Auxiliary Products

- Fan Filter Units (60 SCFM – 50,000 SCFM)

- Condensate Re-Evaporators

- Operator Chair Systems

- Operator Consoles

Slide Title

Write your caption here

ButtonSlide Title

Write your caption here

ButtonSlide Title

Write your caption here

Button

- Direct driven fans (low CFM and total static pressure conditions)

- Backwardly inclined Centrifugal (SWSI or DWDI) fans for higher CFM and total static pressure conditions, belt driven fans

- TEFC, TENV, 1800 RPM, Class F (Option Class H), Insulated, continuous duty motors

- NEMA or IEC contactors

- Heating, which may include SCR control (2 to 70 kW) depending on airflow

- Fire detection systems within air handler

- Motorized damper controls

- Stage 1 - One 24” x 12” x 2” M80 Roughing Filter

- Stage 2 - One 24” x 12” x 2” 40% Medium Efficiency per Ashrae 52-76

- Stage 3 - One 24” x 12” x 4” Gas Filter (Activated Charcoal or Permasorb media)

- Stage 4 - One 24” x 12” x 4” VariCel II 90% High Efficiency filter

- Stage 5 – HEPA (99.97%) Absolute filter

Slide Title

Write your caption here

Button

Spare Parts

Regular scheduled preventive maintenance is a critical component of maintaining your warranty. Regular care preserves and enhances your equipment’s reliability by replacing worn components before they actually fail. Preventive maintenance activities include equipment checks, partial or complete overhauls at specified periods, oil changes, filter changes, lubrication and so on.

We also offer replacement parts for all major components of any of our products and can provide a list of recommended spare parts. Having the right parts on- hand minimizes any unexpected downtime and ensures the continued performance of your HVAC equipment.

- Improved system reliability

- Decreased cost of replacement

- Decreased system downtime

- Protect your warranty

- Extend the life of your equipment

- Reduce down-time